What is solvent deasphalting and why is it an important process in the oil refining industry?

This article explores the overview of solvent deasphalting, how it works, what it is used for, and what SDAs are currently in the market.

OVERVIEW

Solvent Deasphalting (SDA) is a highly efficient crude oil pretreatment– a separation process within the oil refining process typically utilized in a crude oil process or bitumen upgrader. It separates the crude according to molecular type, dissolving certain components and then leaving behind a residue which contains contaminants. The resulting product is deasphalted oil. Essentially, the process of SDA separates the asphalt from the feedstock by dissolving the aliphatic compounds and leaving behind the asphaltenes. The output– de-asphalted oil (often referred to as DAO) and asphalt– is then used for lube oil feedstock, vacuum gas oil (VGO), resid hyrocracking (RHC), conversion feedstock, and as feedstock to hydrocrackers, delayed coking and fluid catalytic cracking units. Its varied uses are dependant on the quality of the resulting DAO.

According to the McDermott website, “SDA produces a low-contaminant, relatively high hydrogen deasphalted oil product (DAO) and a pitch product that contains the majority of the residue’s contaminants (metals, asphaltenes, CCR).”

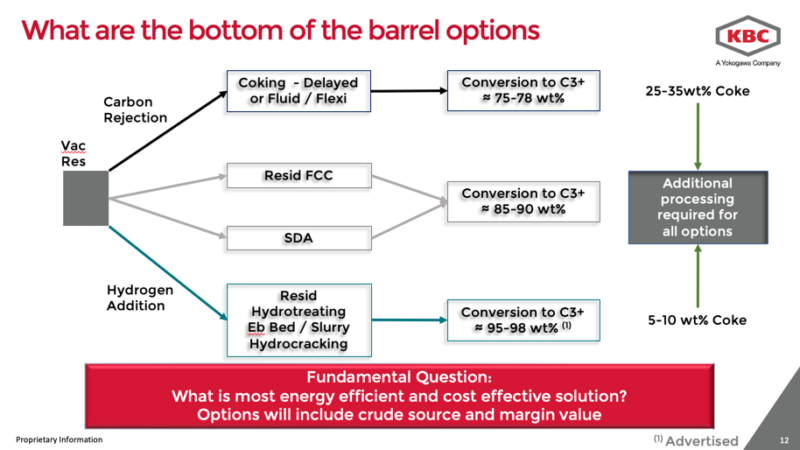

According to a presentation that Mel Larson of KBC delivered at RefComm® Galveston 2019, SDA units can provide a conversion rate of up to 90%.

DIFFERENT DAOs

DAO produced from propane deasphalting contains the highest quality, but also the lowest yield, according to an article on Wikipedia. Whereas “pentane may double or triple the yield from a heavy feed, but at the expense of contamination by metals and baron residues that shorten the life of downstream cracking catalysts.”

As stated above, depending on the quality of the deasphalted oil product, the DAO can be used for many purposes, including the hydrocracker or FCC. And the pitch is often sold as asphalt or utilized in some other conversion processes.

RISKS

The risks associated with Solvent Deasphalting are similar to those in other refining processes. If there is a leak or release of crude from the heaters, a fire could result. Insufficient desalting can result in fouling, which limits product flow and transfer of heat and can cause equipment failures. Corrosion and over-pressurization of the unit can both cause equipment failures. And like all other refining processes, the risk of exposure to the various chemicals used remains a constant for refinery personnel. Safety protocols and personal protective gear should be employed at all times.

SDAs IN THE MARKET

According to its website, Honeywell UOP and Foster Wheeler have designed and licensed more than 70 SDA units, which range in size from 7,000 – 48,000 bpd. McDermott also utilizes SDA for its refining technologies, including LC-FINING, E-Gas gasification technology, and ISOCRACKING.

WANT TO LEARN MORE ABOUT SDA?

SDA is a growing field within the oil refining industry, known for its high efficiency and versatility as a crude separation process. RefComm® 2020 is proudly offering a conference track which focuses on solvent deasphalting and we invite you to attend! Get ahead of the curve with SDA at RefComm® Galveston, where we help you achieve more production with less risk!

Contact us to offer SDA images, text content, case studies or a feature article about your SDA.