How MOC Can Save Lives in the Refinery

Let’s say you have a sink and the faucet handle breaks or rounds off. Then you put pipe wrench on the stub where the faucet handle was to get water in the sink. Sure, you’ve found a workaround to get the water flowing, but you’ve also just…

Women in Refining: Gabi Bergeron

You might say refining is in Gabi Bergeron’s blood. Both of her parents worked in the refining industry so when it was time for the New Orleans native to pick her career track, she already knew what she wanted to do.

Corrosion in the Refinery

My major problem as an operating supervisor in Texas City was corrosion. The common origins of corrosion in an aqueous phase in refinery and process plant applications are HCl, CO2, and SO3. I have not included H2S in this list because H2S, when not interacting with any of the above three molecules, is not particularly corrosive. Also, the above three acids are not corrosive either…

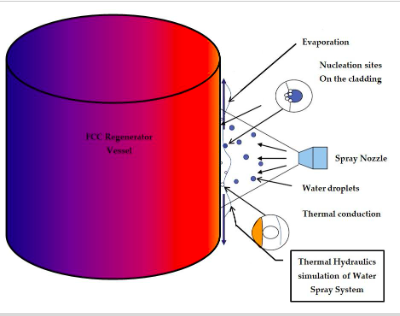

Thermal Hydraulics Simulation in the FCCU…

In the Fluid Catalytic Cracking process, the regenerator is responsible for burning off the coke that has accumulated on the catalyst particles during the cracking reaction. To control the temperature in the regenerator and ensure efficient coke combustion, various cooling methods are employed. There are some common methods used to cool the FCC regenerator…

Optimizing Spray Nozzle and Injector Selection: Full Webinar Recording

The FCC Unit is a workhorse and a huge financial contributor at most refineries. Keeping it running efficiently is a major goal. There are certain spray nozzle and injector applications that can contribute to that efficiency if done properly and if spray technology is better understood.

Revolutionizing Refineries: How Valve Innovations are Optimizing Operations

The refining industry faces a myriad of challenges, including stringent safety regulations, energy consumption concerns, environmental sustainability targets, and the need for reliable asset management. Here are some technological innovations that are…