Dan Gillis - Chevron Lummus Global

Residue Hydrocracking (RHC) has taken to the forefront as the desired residue conversion process in recent years. Several new world-scale projects, not only for residue upgrading and production of transportation fuels, but also crude to chemicals projects, and even production of Low Sulfur Fuel Oil (LSFO) are being based on RHC.

Residue Hydrocracking (RHC) has taken to the forefront as the desired residue conversion process in recent years. Several new world-scale projects, not only for residue upgrading and production of transportation fuels, but also crude to chemicals projects, and even production of Low Sulfur Fuel Oil (LSFO) are being based on RHC.

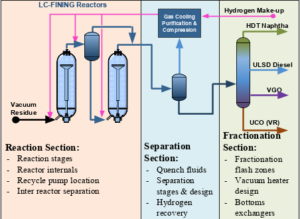

CLG is in a unique position to discuss the merits of RHC as it actively supplies all forms of residue conversion technologies. As well, CLG has expanded LC-FINING’s applications by combining it with other technologies such as coking and solvent deasphalting and with the use of dispersed catalysts to provide cost-effective high conversion solutions. Key to the application of RHC is the assurance that this process is reliable, which has been obtained through continual feedback from the commercial units and advances in equipment and designs.

This presentation provides not just an overview of RHC and its merits for maximizing a refinery’s profitability, but also its impact on a refinery’s capability to produce various products and flexibility for future needs. A comparison of flow schemes is also provided to show how RHC can be integrated into a refinery to maximize production of gasoline, propylene, as well as Petrochemical feed stocks.

Dan Gillis is the Director of Technology for CLG. In this role he provides technology business development and new technology commercialization for CLG’s residue conversion technologies with a focus on high conversion residue upgrading applications, including coking, LC-FINING, LC-MAX and LC-SLURRY. Dan also provides consulting to CLG’s customers on their residue upgrading technology selection and project configuration studies.

Dan Gillis is the Director of Technology for CLG. In this role he provides technology business development and new technology commercialization for CLG’s residue conversion technologies with a focus on high conversion residue upgrading applications, including coking, LC-FINING, LC-MAX and LC-SLURRY. Dan also provides consulting to CLG’s customers on their residue upgrading technology selection and project configuration studies.

Prior to joining CLG, Dan held business management, technology sales management, and engineering management roles for Foster Wheeler and UOP LLC, primarily with their heavy oil processes. Previous to UOP he held various business development, technology development, operations and process engineering roles in refining and heavy oil upgrading organizations.

Dan is a 1977 engineering graduate of the University of Saskatchewan, Canada.