Andrew Shaw - Tracerco Ltd.

To improve margins, refiners continuously look to optimize feedstock blends. Variability can bring significant operational challenges during the refining process that must be overcome. One critical need is the efficient removal of solids, salts, and water from the crude feedstock. This has become increasingly difficult when processing certain opportunity crudes that can have all of these detrimental properties at high levels. These contaminates can have a significant impact on downstream refinery units such as the FCCU and DCU.

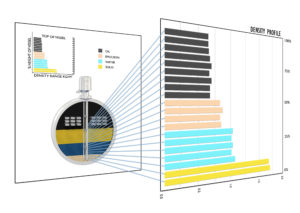

Tracerco offers unique online and non-intrusive measurement and diagnostic technologies to assist operators with modification and optimization projects, enabling maximized production efficiency with minimum cost impact. In this paper the use of radioisotope technology to optimize the performance of desalters will be explored, as will how optimization of the upstream desalter can minimize effects on the downstream process plant.

Case studies to be presented:

- Desalter optimisation project: USA Refinery case study.

- Damage to vessel internals: Impact of contaminants on the downstream process.

- FCCU performance problems

Andrew has more than 18 years of experience working for Tracerco as a process diagnostics engineer, project manager and more recently in business development. He has worked on troubleshooting FCCU process issues all over the world and worked for major companies such as BP, Shell, ConocoPhillips and Equinor. His main area of expertise is in the field of process diagnostics using radioisotope technology.

Andrew has more than 18 years of experience working for Tracerco as a process diagnostics engineer, project manager and more recently in business development. He has worked on troubleshooting FCCU process issues all over the world and worked for major companies such as BP, Shell, ConocoPhillips and Equinor. His main area of expertise is in the field of process diagnostics using radioisotope technology.