Originally appears in Gary Pitman’s Boots on the Ground Series

If it’s installed or engineered, then we need a management of change in order to not follow the protocol.

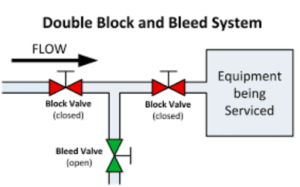

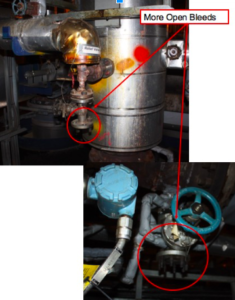

Valves are a tricky business in the coking world. In terms of safety, I have seen a lot of questionable things in my 40+ year career working in refineries. A lot of times the drain valves on coke drums are located in an awkward position, making them hard to access. Or maybe they are rising stem gate valves and are hard to turn because of a little tar in them. In some units I have seen up to 60% of bleed/drain valves with their blind flanges or bull plugs never reinstalled. I see them just lying there on the concrete or decking, or else hanging by one bolt. That, my friends, is our double block and bleed atmosphere.

The other thing we use in the unit is the bull plug. A lot of times bull plugs get heavy oil on them, making them difficult to reinstall, or they get cross-threaded. (By the way, they do have safety-style bull plugs that should be industry standard.)

I always recommend putting ball valves on the DBB there so they’re easier for the operator to turn. And a ball valve reduces the chance of building something (like coke) in the seat pocket.

When it comes to reinstalling blind flanges, bull plugs or blocking in the second valve, we are not following procedure per the unit directives. If it’s installed or engineered, then we need a management of change in order to not follow the protocol.

If you, as an operator, are not using the DBB system, it needs to be tagged and sent up the ladder to upper management explaining what the reasoning is for the valve or system not being double blocked. Because management is assuming the unit is being run according to unit specifications. If we are not running according to spec, we need to let somebody know the reason why. Otherwise the responsibility falls solely on the operator and his team and who wants to shoulder that responsibility?

I would avoid using ball valves as bleeder valves because there’s a risk that they will be turned fully open inadvertently. If the blind flange or bull plug is not installed, this will cause a major incident. This risk is mitigated if the bleeder valve is a gate valve instead of a ball valve.

Yaron thanks for your input!