Alessandra Mara de Bassi Froes - Petrobras

Thiago Amaral - Petrobras

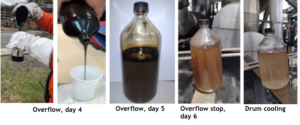

After an uneventful start to the coke drum filling process, where all operational parameters were good, an upset caused cold residue to be fed to the same drum for eight hours. The events that caused this situation, and the unique way the unconverted residue was handled by the engineering and operations teams, will be reviewed. The approach to dealing with the tarry drum scenario did not involve the typical drum steam heating for an extended period. Instead, a light oil was mixed to the unconverted residue, and the drum oil content was overflowed to blowdown system. Learn about our experiences with this procedure and if it can be another tool in your toolbox to deal with these abnormal situations.

Alessandra Mara de Bassi Fróes is a Process Engineer, Coker Consultant for Petrobras. In the last 15 years, she has worked primarily in Delayed Coking Process, including the participation in a new DCU project, its construction inspection, commissioning and start-up. Her current main activity is technical support for the 10 Petrobras DCUs, including troubleshooting, processing and reliability improvement, operators training and turnarounds planning. She holds a B.S. of Chemical Engineering and Project Management MBA.

Alessandra Mara de Bassi Fróes is a Process Engineer, Coker Consultant for Petrobras. In the last 15 years, she has worked primarily in Delayed Coking Process, including the participation in a new DCU project, its construction inspection, commissioning and start-up. Her current main activity is technical support for the 10 Petrobras DCUs, including troubleshooting, processing and reliability improvement, operators training and turnarounds planning. She holds a B.S. of Chemical Engineering and Project Management MBA.

Thiago Paulo Amaral is a Process Engineer, Coker Coordinator for Petrobras. He worked 12 years at Petrobras’ Basic Design Department, mainly in Delayed Coking and Crude Units projects (grassroots and REVAMPS). In the last 5 years he has worked at Petrobras’ Headquarters. His current main activity is Operational and Process management of the 10 Petrobras DCUs. He holds a M.Sc. of Chemical Engineering.

Thiago Paulo Amaral is a Process Engineer, Coker Coordinator for Petrobras. He worked 12 years at Petrobras’ Basic Design Department, mainly in Delayed Coking and Crude Units projects (grassroots and REVAMPS). In the last 5 years he has worked at Petrobras’ Headquarters. His current main activity is Operational and Process management of the 10 Petrobras DCUs. He holds a M.Sc. of Chemical Engineering.