Matt Pretz - Dow Chemical Company

Shale gas produced an imbalance in propylene supply and demand. This has driven the implementation of several projects using available propane dehydrogenation commercial technology. These technologies were adapted from existing processes. These adapted technologies are not tailored to efficiently manage the inherent challenges of catalyst activity, heat input, reaction equilibrium, and unselective thermal reactions. Therefore, the Dow Chemical Company has developed a Catalytic Dehydrogenation Process that is designed from the standpoint of an operating company to efficiently solve the problems inherent in catalytic dehydrogenation processes.

Shale gas produced an imbalance in propylene supply and demand. This has driven the implementation of several projects using available propane dehydrogenation commercial technology. These technologies were adapted from existing processes. These adapted technologies are not tailored to efficiently manage the inherent challenges of catalyst activity, heat input, reaction equilibrium, and unselective thermal reactions. Therefore, the Dow Chemical Company has developed a Catalytic Dehydrogenation Process that is designed from the standpoint of an operating company to efficiently solve the problems inherent in catalytic dehydrogenation processes.

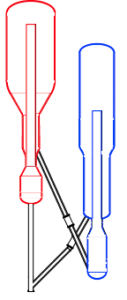

The new technology is a circulating fluid bed technology based on existing Fluid Catalytic Cracking (FCC) technology. The Dow process utilizes a proprietary catalyst with a proprietary reactor and regenerator design to achieve 45% propane conversion at approximately 93 mol% selectivity to propylene. The simplicity of the system enables capital savings greater than 20% versus other commercial offerings. In addition, the higher conversion at moderate pressure reduces the energy requirement per pound of propylene.

This new technology can be fully integrated with existing ethylene crackers in parallel with new or existing furnaces. In this way, a producer can increase production in an existing light hydrocarbon facility or build a new facility with exactly the amount of ethylene and propylene product that is desired based on ethane and propane feeds. Dow is currently planning a project to implement this technology in an existing cracker at commercial scale and would license the technology upon request.

Matt Pretz is a Research and Development Fellow of the Dow Chemical Company with 22 years of experience in R&D and Manufacturing. Matt invented, piloted, and scaled up Dow’s Fluidized Catalytic Dehydrogenation (FCDh) technology. He is the principal designer and process expert for the FCDh, which was recognized as the 2017 R&D 100 winner and 2017 ICIS Best Process Innovation winner. Matt’s vision is to develop breakthrough technologies for the chemical industry to revolutionize conventional olefin production processes. He has been granted 17 patents and has 20 patents pending.

Matt Pretz is a Research and Development Fellow of the Dow Chemical Company with 22 years of experience in R&D and Manufacturing. Matt invented, piloted, and scaled up Dow’s Fluidized Catalytic Dehydrogenation (FCDh) technology. He is the principal designer and process expert for the FCDh, which was recognized as the 2017 R&D 100 winner and 2017 ICIS Best Process Innovation winner. Matt’s vision is to develop breakthrough technologies for the chemical industry to revolutionize conventional olefin production processes. He has been granted 17 patents and has 20 patents pending.