Dale Wilborn - Chevron El Segundo

Justin Reeves - Chevron El Segundo

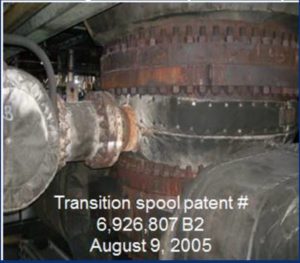

The Chevron patented specially designed Coker drum inlet transition spool has the following features:

- No moving parts

- No steam injection

- No operator permissive or special procedural steps.

- Reduces water channeling, allows relatively even distribution to extend coke drum life.

The design has been in service since 2003 in El Segundo. The presentation will cover the history, the original Salt Lake and Pascagoula spool design issues and performance. The primary purpose of the resid inlet technique is to reduce the likelihood of coke drum damage – bulges, cracks and tilting (banana). Coke drum quench TI trends to infer water distribution are the best way to project future coke drum effects. Coke drum laser scans and other inspection techniques after a number of years in-service is the “report card.”

Dale Wilborn has worked for Chevron for 38 years in engineering, operations, and El Segundo Coker capital project roles. He is currently (since 4th Q 2012) Chevron’s Coker Business Improvement Network (BIN) leader. Under his project management, El Segundo installed automated bottom unheading in 2003 and the industry’s first automated top unheading system in 2004.

Dale Wilborn has worked for Chevron for 38 years in engineering, operations, and El Segundo Coker capital project roles. He is currently (since 4th Q 2012) Chevron’s Coker Business Improvement Network (BIN) leader. Under his project management, El Segundo installed automated bottom unheading in 2003 and the industry’s first automated top unheading system in 2004.