Words and images courtesy of Integrated Global Services

How Tube Tech helped increase thermal efficiency by 3% at Tüpraş Izmir Refinery. Tube Tech deployed its patented fouling removal robot to tackle fouling within a steam methane reformer furnace’s convection bank tubes. The unit had never been cleaned since coming into service in 1993 due to the inaccessible location of the convection tubes.

The Problem

The plant was experiencing reduced heat transfer, higher fuel consumption and an increase in the flue gas temperature of its steam methane reformer. The problems arose from the adsorbents in a Pressure Swing Absorption Unit, part of the refinery’s Hydrogen Manufacturing Unit (HMU), being changed during a turnaround.

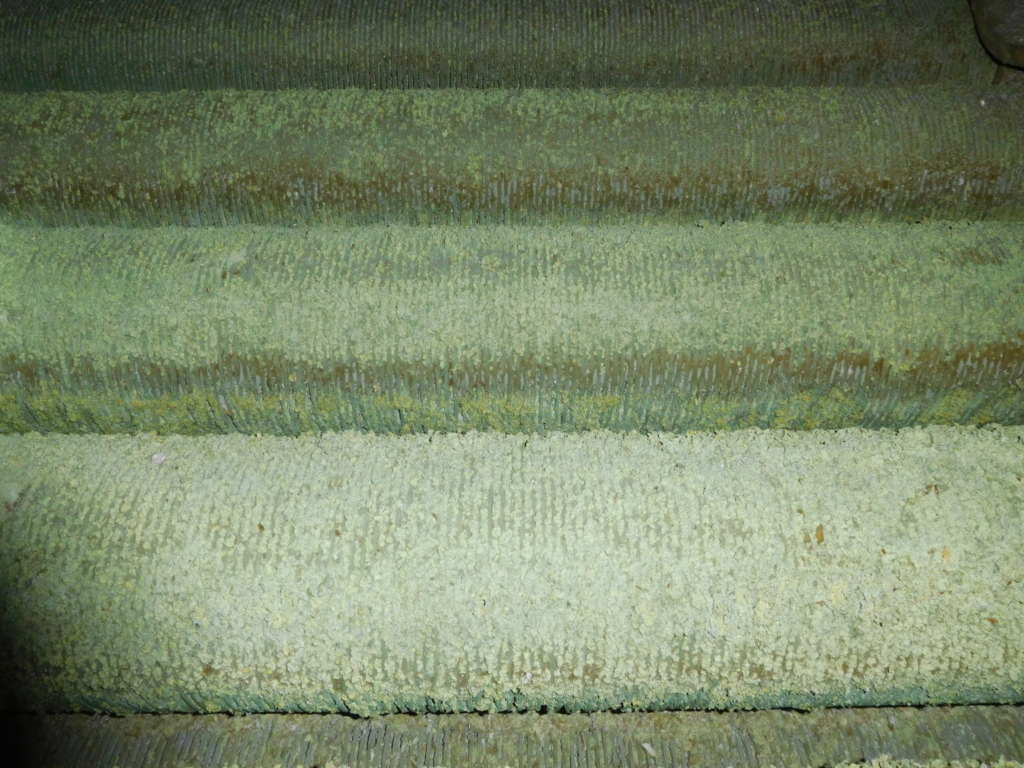

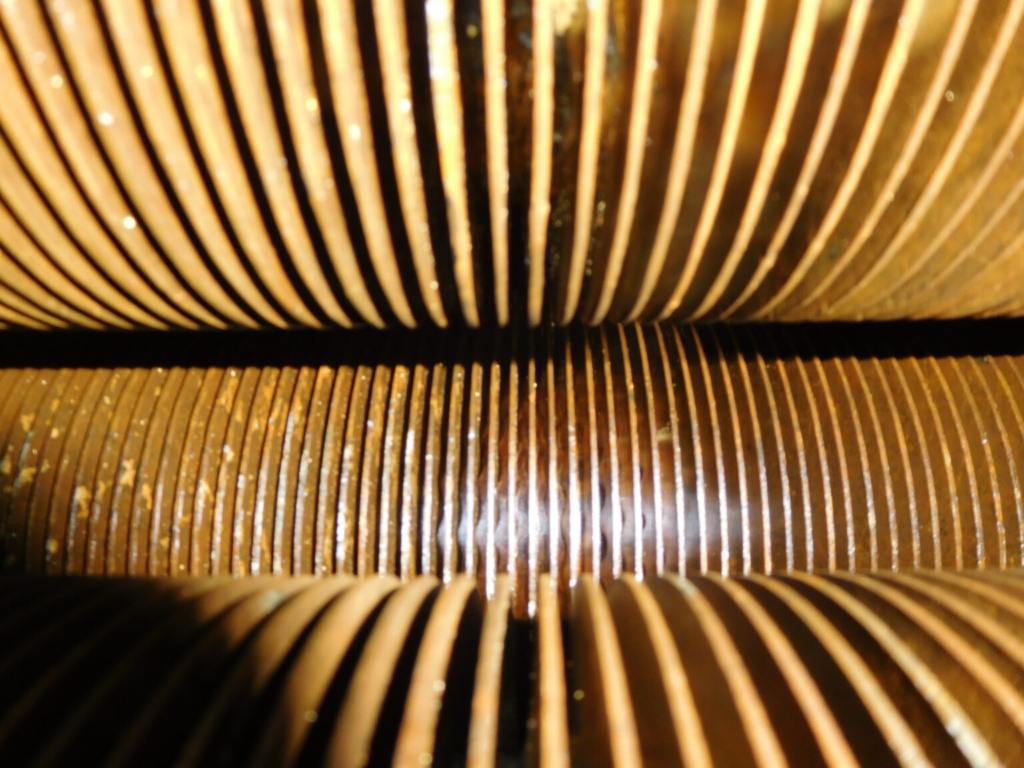

Once started up, some of these adsorbents were transported by the tail gas stream and facilitated by misplaced screens in one of the beds; the result was an accumulation of fouling on the convection bank tubes of the steam methane reformer.

The Solution

To restore heat transfer, the decision was made to conduct a cleaning of the convection section tubes. The client contacted Tube Tech as a provider of engineered cleaning solutions with particular expertise in accessing even the hardest-to-reach areas.

IGS’s team mobilized during the planned turnaround period and deployed its patented fouling removal robot, which can penetrate deep between tube rows to remove 90%+ fouling. Traditional cleaning methods would only be able to clean approximately 30% of the convection bank. Cleaning was complete within 60 hours.

The Results

Hydrogen Production Cost and ROI

The average cost of hydrogen production before and after the project was calculated at $943.9-919.3 $/t. The production cost of hydrogen decreased by $24.6/t and the payback period for the project was less than 60 days.

Flue Gas Temperature

The average flue gas temperature decreased from 278°C to 220°C, meaning that the furnace’s thermal efficiency increased by approximately 3%.

Steam Production

Steam production increased by approximately 20%, and the generated steam temperature increased by 10°C-15°C.

As well as Tube Tech’s fouling removal services, the refinery also utilized another IGS solution by applying a Cetek high-emissivity coating onto the refractory surface to increase radiant section efficiency. Click here to read more.

For more information, visit https://tubetech.com/case-study/tube-tech-helps-increase-thermal-efficiency-by-3-at-tupras-izmir-refinery/