Emory Weber - Refined Technologies, Inc.

Heat transfer limitations routinely affect refinery throughput and energy efficiency. Heat exchanger maintenance programs are devised within the refinery to ensure that these limitations have minimal impact on utilization. Most maintenance programs require heat exchanger bundles to be taken off line for long periods of time and mechanically cleaned, typically via hydroblasting, before they can be reinstalled and placed back in service. This costly process can take several weeks, during which heat exchanger availability and unit throughput are often reduced.

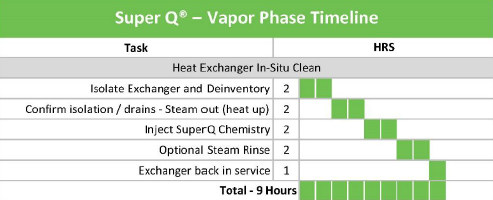

The cost of maintenance programs and availability of heat exchangers can be improved by adding in-situ chemical cleaning to extend the time between pulling bundles and hydroblasting. Refined Technology Inc. (RTI) has patented chemistry and process technology that can restore heat transfer by cleaning the exchanger in place in a fraction of the time it takes to pull the bundle and hydroblast. Onsite preparation and setup time for in-situ cleaning applications is typically less than four hours followed by a two-hour chemistry injection window and optional two-hour steam rinse before returning the exchanger to service.

The cost of maintenance programs and availability of heat exchangers can be improved by adding in-situ chemical cleaning to extend the time between pulling bundles and hydroblasting. Refined Technology Inc. (RTI) has patented chemistry and process technology that can restore heat transfer by cleaning the exchanger in place in a fraction of the time it takes to pull the bundle and hydroblast. Onsite preparation and setup time for in-situ cleaning applications is typically less than four hours followed by a two-hour chemistry injection window and optional two-hour steam rinse before returning the exchanger to service.

Pulling, hydroblasting, and reinstalling the bundle can be minimized by in-situ cleaning. This translates to cost, safety, and availability improvements. Additionally, RTI’s technology can be implemented with refinery personnel and is proven to be more cost effective than alternative cleaning methods.

Emory graduated the University of Texas in 2011 with a Bachelors Degree in Chemical Engineering and joined RTI in 2017 as the director of Business Development serving the Houston and Corpus Christi markets. Prior to joining RTI, Emory’s career included roles in process and production engineering at multiple US Gulf Coast refiners.

Emory graduated the University of Texas in 2011 with a Bachelors Degree in Chemical Engineering and joined RTI in 2017 as the director of Business Development serving the Houston and Corpus Christi markets. Prior to joining RTI, Emory’s career included roles in process and production engineering at multiple US Gulf Coast refiners.