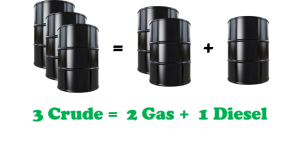

Strong U.S. refining margins reflected in the 3-2-1 crack spread (i.e., profit from processing 3 barrels of crude into 2 barrels of gasoline & 1 barrel of diesel) supported by an uptick in product exports continue to encourage high refinery utilization rates. Gulf Coast and Midwest refiners in particular, are prospering from an unanticipated surge in domestic demand for gasoline and diesel. Nonetheless, many refiners are taking a wait and see approach to expanding capacity and product diversity. This includes refiners in other parts of the world. Lower interest rates may be affecting refiner’s access to investment capital. However, while the refining sector is the only profitable sector in the energy industry (refined product prices don’t drop as fast as crude oil prices), they may be waiting for the other shoe to drop if the downturn in oil production continues into 2016.

Or perhaps refiners just don’t want to spend money on new projects until they really have to, which in many instances, are environmentally compelling projects. For example, small North American refiners (< 100,000 bpd), represented by one-third of U.S. refining capacity, don’t need to meet Tier 3 sulfur specifications until 2020, allowing those refiners to spread out capital investment over a longer period of time. Some of the larger refiners can also delay capital spending to meet Tier 3 requirements by using credits earned in meeting existing Tier 2 sulfur limits (< 30 ppm sulfur). This may give refiners more time to plan on how they are going to deal with strategic challenges encountered with processing higher volumes of unconventional crudes.

Mexico’s national oil company Petróleos Mexicanos (PEMEX) said in February 2014, that it will postpone refinery upgrades needed to produce low-sulfur gasoline and diesel as part of about $4 billion in budget cuts that it needs to make this year in response to sharply lower oil prices. PEMEX said in a statement that its board of directors approved budget cuts that would delay previously announced plans to upgrade its six refineries, including its $2.8 billion clean-fuels program announced in September before the worst of the plunge in global oil prices. PEMEX said its budget cuts were of such magnitude—nearly 12% of its planned expenditures in 2015—that it was forced to apply the austerity measures to the capital-intensive refinery upgrades, including the clean-fuels program.

Projects in other refining regions continue to go forward. In early April, KBR announced that it has been awarded a reimbursable contract by Flint Hills Resources (FHR) for the modification and expansion of its Corpus Christi West refinery (FHR also operates a Corpus Christi East refinery). Under the terms of the contract, KBR will provide construction management and direct hire construction services at FHR’s Project Eagle Ford. This work is expected to be performed in phases over the next three years and is in addition to a previously announced contract for construction advisory services being performed as the client completes the front end engineering and detailed design (FEED) phases of the project. KBR personnel have been, and will remain, fully integrated with the client and a multitude of other contractors on the project.

In the not too distant future, recently built refineries, such as those in Saudi Arabia, with an average 400,000 bpd capacity and little to no light tight oil (LTO) processing experience, will have “to reset” their new process assets to run shale-based LTOs blended with conventional crudes (e.g., Arab Heavy). In late 2013, Saudi Aramco announced plans to invest about $3 billion in developing its country’s nascent shale resources in the Red Sea and elsewhere. Then in 2014, they upgraded the planned investment to $9 billion. Refining of unconventional crudes, and the capital investment required to achieve this, is a global phenomenon and is to be discussed in detail at the May 4-8 RefComm Galveston 2015 Refining Conference (www.refiningcommunity.com/galveston2015).