Darshan Sachde - Trimeric Corporation

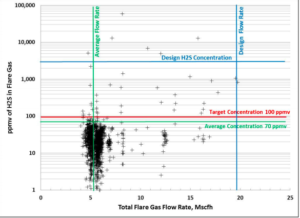

Many refineries have flare gas streams that contain sulfur compounds, especially H2S, which need to be removed from the gas so that it can be flared or used as fuel gas elsewhere in the plant. Different technologies can be used to remove the H2S from flare gas streams including amine treating, caustic scrubbing, solid scavengers, and liquid scavengers. In this paper, a brief overview of these technologies is presented first followed by in-depth discussions on how the characteristics of the flare gas stream impact the design and performance of the different H2S treating technologies. For example, it is critical that a good design basis is established since the H2S treating equipment usually must be sized to handle the maximum flare gas flow rates, H2S concentrations, and H2S loadings as well as typical operating conditions. Examples of the variation of these parameters observed in the field and some of the criteria used to define an appropriate design basis are provided. The effect of operating temperature and pressure on the various H2S treatment processes is also discussed. The effects of key species in the flare gas stream (carbon dioxide, ammonia, hydrogen, oxygen, water, hydrocarbons, and H2S) are also described. Descriptive examples and illustrations of how each of these parameters impacts the H2S removal technologies are provided. This will help refiners better understand when certain H2S removal processes are more applicable so that the most appropriate technology can be selected.

Many refineries have flare gas streams that contain sulfur compounds, especially H2S, which need to be removed from the gas so that it can be flared or used as fuel gas elsewhere in the plant. Different technologies can be used to remove the H2S from flare gas streams including amine treating, caustic scrubbing, solid scavengers, and liquid scavengers. In this paper, a brief overview of these technologies is presented first followed by in-depth discussions on how the characteristics of the flare gas stream impact the design and performance of the different H2S treating technologies. For example, it is critical that a good design basis is established since the H2S treating equipment usually must be sized to handle the maximum flare gas flow rates, H2S concentrations, and H2S loadings as well as typical operating conditions. Examples of the variation of these parameters observed in the field and some of the criteria used to define an appropriate design basis are provided. The effect of operating temperature and pressure on the various H2S treatment processes is also discussed. The effects of key species in the flare gas stream (carbon dioxide, ammonia, hydrogen, oxygen, water, hydrocarbons, and H2S) are also described. Descriptive examples and illustrations of how each of these parameters impacts the H2S removal technologies are provided. This will help refiners better understand when certain H2S removal processes are more applicable so that the most appropriate technology can be selected.

Darshan Sachde is Senior Process Engineer for Trimeric Corporation, a chemical engineering services company located in Buda, TX. Mr. Sachde obtained his B.S. and Ph.D in chemical engineering from the University of Texas in Austin. He has extensive experience in a wide range of chemical engineering industries and applications including oil refining, polymer processing, semiconductor manufacturing, uranium processing, and CO2 capture from power plant flue gas with amine solvents. Mr. Sachde has specific experience with molten sulfur processes (e.g., conceptual design of molten sulfur tanks, sulfur tank vent gas scrubbing, sulfur degassing technologies) and flare systems (e.g., seal pot design, H2S removal technologies, flare gas recovery) in oil refining applications.

Darshan Sachde is Senior Process Engineer for Trimeric Corporation, a chemical engineering services company located in Buda, TX. Mr. Sachde obtained his B.S. and Ph.D in chemical engineering from the University of Texas in Austin. He has extensive experience in a wide range of chemical engineering industries and applications including oil refining, polymer processing, semiconductor manufacturing, uranium processing, and CO2 capture from power plant flue gas with amine solvents. Mr. Sachde has specific experience with molten sulfur processes (e.g., conceptual design of molten sulfur tanks, sulfur tank vent gas scrubbing, sulfur degassing technologies) and flare systems (e.g., seal pot design, H2S removal technologies, flare gas recovery) in oil refining applications.